Initial situation

Companies have to comply with environmental and social standards within their supply chains, they also have to seamlessly control and be able to verify them at any given moment of time. To ensure that companies know their supplier network well enough, independent audits of production sites and certifications come into play. The supplier networks are becoming more and more global and highly complex, which often results in further challenges for the auditing of the players and tracking of delivery and manufacturing processes. These challenges can be:

- Global supplier networks are highly complex and include players from different countries. Various documentation platforms lead to breaks in traceability or make the documentation of the supply chain time-consuming and susceptible to manipulations.

- The public demand for transparency on the part of politicians and consumers is growing, so that companies have to provide clear information about the origin of their goods and the stakeholders involved.

- Proof of adherence to the necessary compliance requirements in the form of environmental, social and safety standards along the entire value chain is only possible through regular and cost-intensive auditing.

- Companies do not want to give up their competitive advantage of their own anonymous supplier pool, which prevents cooperation with other players.

The goal

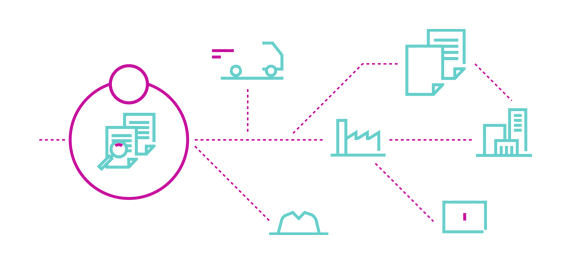

Digital Identities of product batches in the blockchain must help map the entire value chain digitally and tamper-proof. Various stakeholders participating in the added value creation cooperate across companies, create common standards and thus, increase efficiency in supply chain management. At the same time, the sovereignty and security of their data are guaranteed.

The solution

The Business Blockchain evan.network (powered by EPN) allows the 100% reliable documentation of complex supply chains and the cross-company cooperation of different stakeholders in a neutral network. Based on Digital Identities of products or product batches, the players can exchange delivery data, product information and certificates digitally and forgery-proof, even if they do not know each other. Through a continuous, tamper-proof exchange of the current process, supply chains are optimized across companies and the stakeholders involved retain their anonymity and control over their data.

By doing so, companies can generate attractive offers far beyond their own services. The clear identification of a machine and its always available tamper-proof digital service and machine history enable faster maintenance work and increase the availability of the machine and its resale value.

Use at a glance

- Products are made available as Digital Identities: they become a part of the digital process, where delivery data, product information, and certificates can be standardized and exchanged between cooperation partners in a forgery-proof manner

- Increased efficiency of administrative processes through the elimination of media breaks and consistent digital documentation

- Verification of the Digital Identity of each network member and thus an increase in trust and transparency in the value chain

- Preservation of the anonymous supplier pool with simultaneous traceability of the certification status across the entire value chain

- Traceability of products through Smart Contracts which provide material, order and batch numbers linked with each other

- Transparent presentation of certificates from the entire value chain which are digitally issued by independent audit organizations and stored in a tamper-proof manner

- Consistent tracking of goods deliveries across many manufacturing and transport companies

Best Practice: digital and transparent

supply chain management at KiK

On the basis of the Business Blockchain evan.network (powered by EPN), various players of the textile industry are able to demonstrate compliance with CSR standards throughout the entire supply chain. By combining different manufacturers and regulatory authorities to form a value-added network, the costs and efforts for auditing are significantly reduced. In addition, it is possible to share former audits with partners.

Digital Identities are created for participating suppliers and certified by trustworthy authorities (e. g. TÜV or BMZ). The production batches of these certified suppliers are mapped on the blockchain as Digital Identities and are certified to be counterfeit-proof. This means that the necessary certification of all the participating partners can be proven for each production batch. At the same time, the suppliers can maintain their anonymity: Only the certification status of the batch, not the respective name, is documented and controlled. Within the digital supply order, other members of the supply chain can only see the participation of a certified company. On this basis, a trustworthy certification proof can be created within the supply chain, simultaneously preserving the data sovereignty of all actors.